Error Log

There are lots of things that set our Infinitybox wiring system apart from traditional harnesses. Our troubleshooting and diagnostics is probably one of the most significant features that we offer. The system will tell you where there are problems in the wiring harness, with no tools required.

One of the more significant features that is built into every one of our systems is our Error Log. This is an advanced troubleshooting tool that can help to identify problems with a system installed in any vehicle. The system actively monitors key parameters in the wiring harness. If these go out of their expected range, the MASTERCELL stores these errors and has the capability to display them back for problem solving.

Let’s start with a deeper dive into how the system works. When you turn on a switch, the MASTERCELL sees the input get grounded. It sends a signal to the POWERCELL to turn on an output. Before the POWERCELL can turn on that output, it needs to check to make sure that everything is safe to do so. There are three critical parameters that the POWERCELLs check before they can turn on an output: the primary battery voltage, the charge pump voltage and the POWERCELL temperature. The POWERCELL is continuously monitoring these values and making decision on what to do with them.

The primary battery voltage is an easy one. The voltage that the POWERCELL is fed from the battery has to be in a specific range. A charged battery should be at about 12.8 volts. When the engine is running and the alternator is charging, that voltage should be between 13.8 to 14.2 volts. The Infinitybox system has internal high and low limits that it watches for the primary battery voltage. The system can operate down to 6.5 volts and up to 19.0 volts. If the measured voltage goes outside of these limits, the POWERCELL will shut the outputs off for safety. In general, your system should be operating between 12.2 and 14.2 volts. If you’re outside of that, you have a battery or charging issue.

The next one is charge pump voltage. This is an internal measurement that we take to assess the health of the POWERCELL. A charge pump is exactly what it sounds like. We have circuitry on the board that pumps up a charge and stores it. This stored charge is used to turn the MOSFETs on. We don’t use relays on the POWERCELL, we use solid-state MOSFETs. These can do a lot more than a relay but they need to be turned on a specific way. That’s what the charge pump does. We monitor the charge pump voltage and display it as part of the POWERCELL statistics. Depending on the software version, some systems will display CP Volts. Other systems may display CP Delta. If your system shows CP volts, this number should be above 22-volts. If your system shows CP Delta, it should be above 12.0. Again, this in an internal measurement that we use to assess the health of the POWERCELL.

The last measurement that we take is board temperature. Each board has a small temperature sensor mounted on it. This lets the processor monitor the temperature on the printed circuit board. This temperature is a combination of the heat generated on the board and the heat from the environment that the POWERCELL is mounted in. All of the components on the POWERCELL boards are rated to 125 degrees Celsius (257 degrees Fahrenheit). If the board temperature measured by the processor approaches this 125 C limit, it shuts the outputs down for safety.

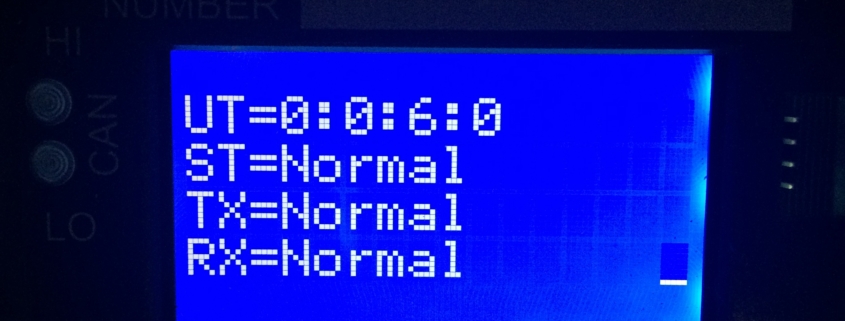

So lets look at the error log. If a POWERCELL records an error, it sends it to the MASTERCELL which stores it in a list. The MASTERCELL stores 8 errors. New errors that are recorded push the oldest errors out of this list. The MASTERCELL reports the Uptime when the error was recorded, the cell that reported it and the outputs associated with it. The uptime is a clock that starts when the system is powered up. You can see this when it is running normally. This is not a real-time clock because it does not continue to run when the system is shut down.

To get to the error log, you first remove the clear cover from the MASTERCELL. Then you press and release the HOME and SCROLL DOWN buttons under the screen. Hold them together for one second then let them go. The MASTERCELL will display any errors that it has stored. If you want to stop the error log process at any time, simply press and hold the HOME button for 5 seconds.

Our technical support team can learn a lot about your electrical system by looking at the events recorded in the error log. It is usually easiest for you just to record a video of the error log running with your smart phone and send that to our team. We can analyze it for you.

By looking at the events in the error log, we can identify problems with your grounds, your battery, your charging system and how you have the system installed in your car. Check out this video to learn more.

Contact our technical support team if you have any questions about our error log, our diagnostics, our troubleshooting capabilities or any other questions related to our Infinitybox wiring system.

Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.  Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox 2022. All Rights Reserved.

Copyright Infinitybox 2022. All Rights Reserved.  Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.  Image Courtesy of Miranda Built, Inc.

Image Courtesy of Miranda Built, Inc.  Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.  Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.  Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.

Copyright Infinitybox, LLC 2021. All Rights Reserved.

Leave a Reply

Want to join the discussion?Feel free to contribute!