Wiring an LED

We got another great question from a customer today. This one came in through our Facebook page.

“I’m going to be running LED headlamps and taillights on my Infinitybox-equipped car. Can you write-up a blog on the changes I’ll need to make in my wiring?”

Here are the changes that you need to make when wiring an LED light with the Infinitybox system: absolutely nothing.

Our POWERCELLs turn things on and off including fans, ECU’s, pumps and lights. Lights come in basically two flavors: incandescent and LED. Incandescent lights were the original creation of Thomas Edison. Up until a few years ago, they were used for all of the lights in cars including headlights, running lights, interior lights, brake lights and turn signals.

The trend in automotive lighting is towards LEDs or light emitting diodes. This link will take you to a Wikipedia page talking about how they work. LED’s have two main advantages of incandescent light bulbs. First, they have no filaments or fragile parts so they last a long time. Second, they are much more efficient than incandescent bulbs. This means that they consume much less current to get the same level of brightness.

To go back to the question, you can connect an LED light in the place of an incandescent bulb and it will work correctly when connected to an Infinitybox POWERCELL. The other question that we usually get related to LED’s is “do I need a load resistor when using LED turn signals?”. The answer again is “no”.

Traditional turn signal flashers work by drawing current through a heating element within the flasher. The flashers are expecting a certain amount of current being drawn by an incandescent bulb. When you change to LEDs with a traditional turn signal flasher, you needed to add a load resistor that draws current through the circuit. This compensates for the reduced current flowing through the LED.

With the Infinitybox system, you don’t need the load resistor to get your turn signals to work correctly. We do the flashing of the turn signals and 4-ways through the processor on the POWERCELL. The flashing does not depend on the amount of current flowing to the bulb. To the POWERCELL, there is no difference between an incandescent bulb or an LED light.

To round out this question, there is one thing that you may need to do when wiring an LED into your Infinitybox system. As we mentioned above, LEDs are much more efficient than their incandescent cousins. It takes very little current to turn them on. LEDs from different manufacturers are more or less efficient, depending on the materials that they may use.

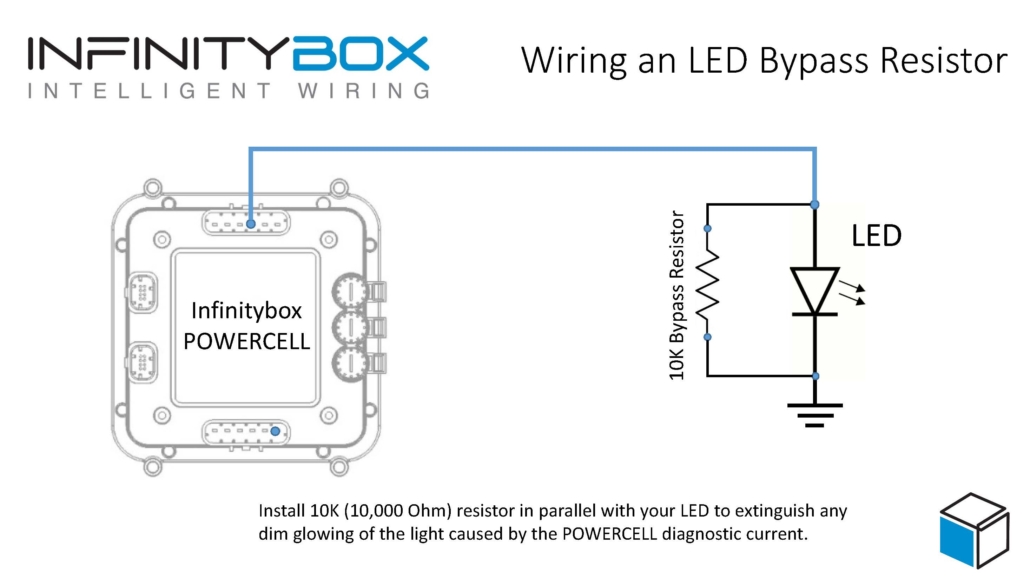

Our POWERCELLs leak a very small amount of current out of the outputs. We use this as part of our diagnostic system. Depending on the efficiency of the LED, this diagnostic current may make the LED’s glow dimly when the light is off. To eliminate this, you can simply connect a 10K (10,000 ohm) resistor between the POWERCELL output wire and ground. An 1/8 Watt resistor or larger will be fine. This picture shows you how to wire this in.

This bypass resistor shunts the diagnostic current through the resistor around the LED. You can pick up a 10K resistor on-line.

You can download a PDF of this wiring diagram by clicking this link.

Please give our technical support team a call if you have questions about this post.